Lift, drive, store:

Wide range for weaving

The bottleneck in in-plant transport in weaving mills is the pickup and delivery of the heavy rolling loads. The safer the handling and logistics technology for people and materials, the more reliably delivery deadlines can be met.

In addition to advanced warehouse management, efficient intralogistics is an important prerequisite for responding flexibly and reliably to an unexpected increase in demand for specific fabrics. Genkinger offers a wide range of transport solutions, especially for weaving mills.

- Warp beam transport, warp beam change

- Fewer personnel thanks to efficient lifting aids through to automated guided vehicles (AGVs)

Everything under control in the weaving & knitting mill

Sovereign security

in any situation

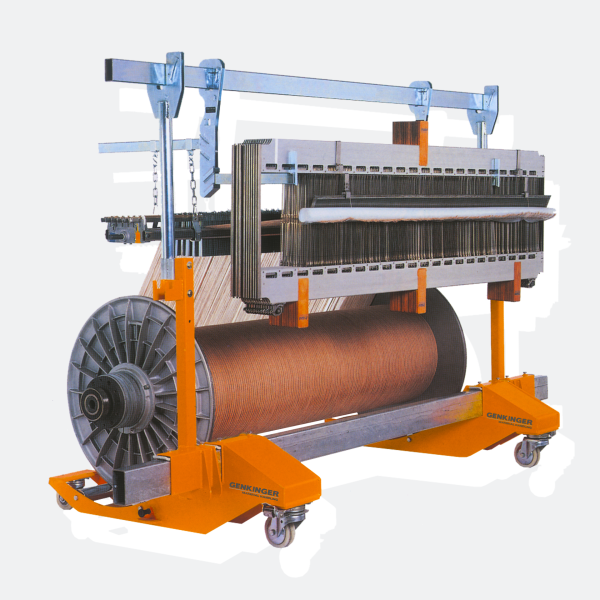

When transporting docks and merchandise trees, it is important to solve these three situations in particular with confidence:

- The removal of the dock from the dock winder or the removal of the fabric beam from the weaving machine

- The safe transport, also over longer distances, on small and also uneven surfaces

- The safe unwinding of the dock or fabric beam down to the floor, to intermediate heights or up to the high rack

Genkinger develops customized transport solutions for docks and goods trees with different weights, lengths and diameters, always also adapted to the conditions and requirements on site.

- Docks & fabric trees up to 3,000 kg

- Different lengths and diameters

- Also double-sided overrolling and unrolling from the floor to the high rack

Project

KEGU 50: Transport trolley

- Load capacity Q 5.000 kg

- Machine width 600 mm - infinite

Project

EE-DKHUM 20...30: Low lift truck

- Load capacity Q 2000 kg, 3000 kg

Project

WB 3...7: Low lift truck

- Load capacity Q 300 kg, 500 kg, 700 kg

Project

EE-GM 25...30: Transport trolley

- Load capacity Q 2.500 kg

- Machine width 600 mm - infinite

Describe your case.

We will be glad to advise you.

Describe your case.

We will be glad to advise you.

This is where Genkinger comes in:

We will also find a suitable solution for your transport challenge

Textile technology for advanced students:

Warp beam change

with weaving harness

For a flexible article change in weaving mills, drawn-in warps must be kept ready on the one hand and picked up, transported and stored in an orderly manner on the other. Warp thread breaks during the changing process and storage must be avoided.

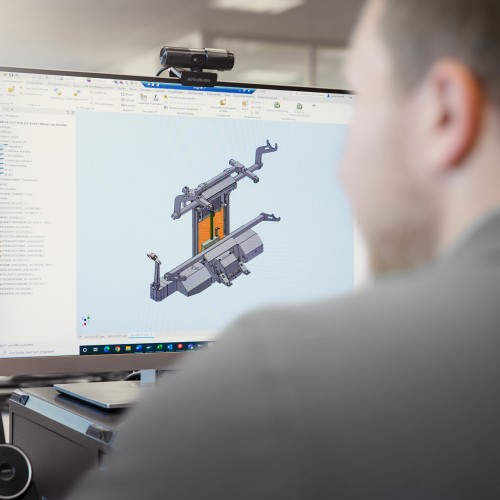

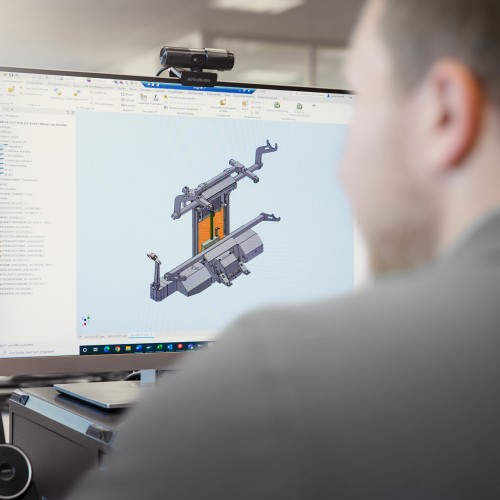

Genkinger has been developing special and standard vehicles as well as devices for the textile industry since 1955. Experienced specialists are needed for individual solutions, especially for warp beam changing including weaving harness.

- Special vehicles and devices for changing drawn-in chains

- For different machine types and widths

- Narrow aisles, full and half warp beams

Project

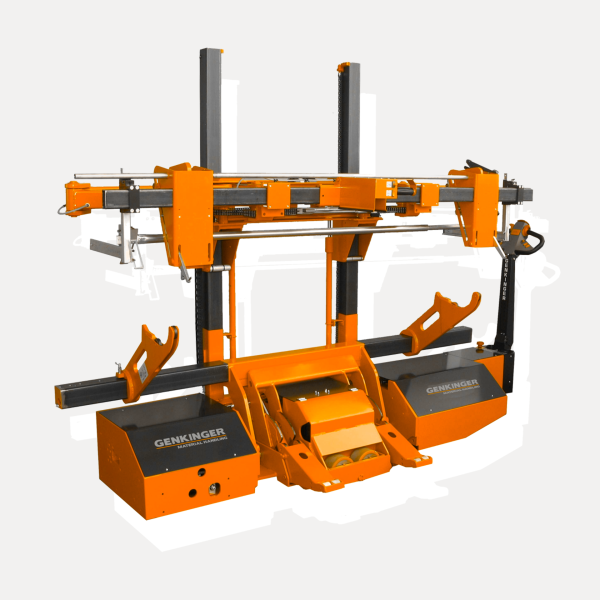

EE-KHUR 20...50 GEV: Dish storage trolley

- Load capacity Q up to 5.000 kg

- Machine width 1.200 mm - infinity

Project

TLS 20...30: Transport trolley

- Load capacity Q 2000 kg, 3000 kg

- Machine width 600 mm - infinite

Describe your case.

We will be glad to advise you.

Describe your case.

We will be glad to advise you.

This is where Genkinger comes in:

We will also find a suitable solution for your transport challenge

Things run smoothly with us:

Safe on all

ways through the

weaving and knitting

Special lifting and transport vehicles are needed for inserting, changing and storing warp beams. This is because roll-shaped heavy loads such as warp beams require particularly safe handling.

Genkinger has been the specialist for lifting and transport vehicles for warp beams for many decades. We are in close exchange with leading textile machinery manufacturers to equip small and large textile companies around the world with innovative transport and material handling systems for warp beams.

- Transport and insertion of upper and lower warp beams

- Warp beam change with harness

- For full warp beams, half warp beams, warp beams and canisters

- High lift truck, low lift truck, transport truck

Project

EE-GYR 25: High lift truck

- Load capacity Q 2.500 kg

- Machine width 1.100 mm - infinite

Project

KEGU 50: Transport trolley

- Load capacity Q 5.000 kg

- Machine width 600 mm - infinite

Project

EE-KHHR 20: High lift truck

- Load capacity Q 2.000 kg

- Machine width 1.400 mm - infinity

Project

EE-KHUR 20...25: Low lift truck

- Load capacity Q up to 2.500 kg

Describe your case.

We will be glad to advise you.

Describe your case.

We will be glad to advise you.

This is where Genkinger comes in:

We will also find a suitable solution for your transport challenge

Highlights