Textile technology for advanced students:

Warp beam change

with weaving harness

For a flexible article change in weaving mills, drawn-in warps must be kept ready on the one hand and picked up, transported and stored in an orderly manner on the other. Warp thread breaks during the changing process and storage must be avoided.

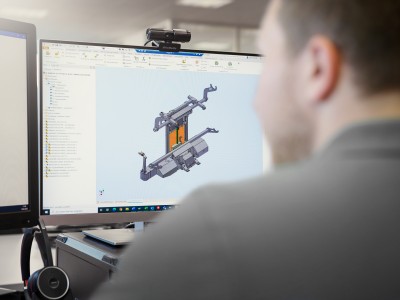

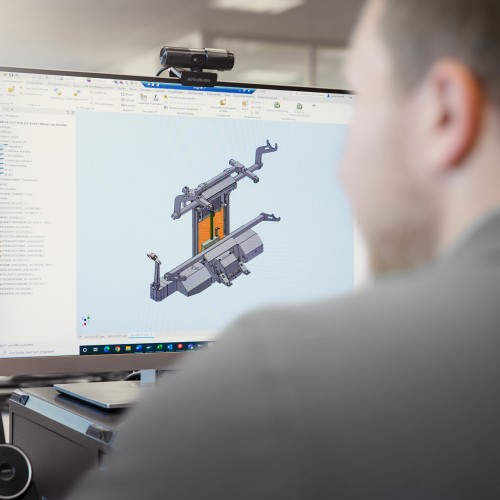

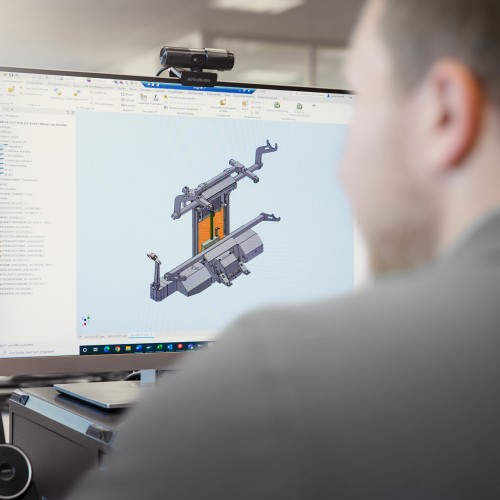

Genkinger has been developing special and standard vehicles as well as devices for the textile industry since 1955. Experienced specialists are needed for individual solutions, especially for warp beam changing including weaving harness.

- Special vehicles and devices for changing drawn-in chains

- For different machine types and widths

- Narrow aisles, full and half warp beams

up to 5.000 kg

For a smooth transition at the:

Loading and unloading

The efficiency of material handling is decided during loading and unloading. This is because the transition situation involves risks for people and material. And costs time. Especially with heavy loads, bulky or round loads, little space, demanding pick-up and unloading systems, takeovers from the most varied heights.

The more specified the transport solution, the faster and safer loading and unloading are completed. As ergonomic as possible. Or optionally driverless, completely automatically.

Project

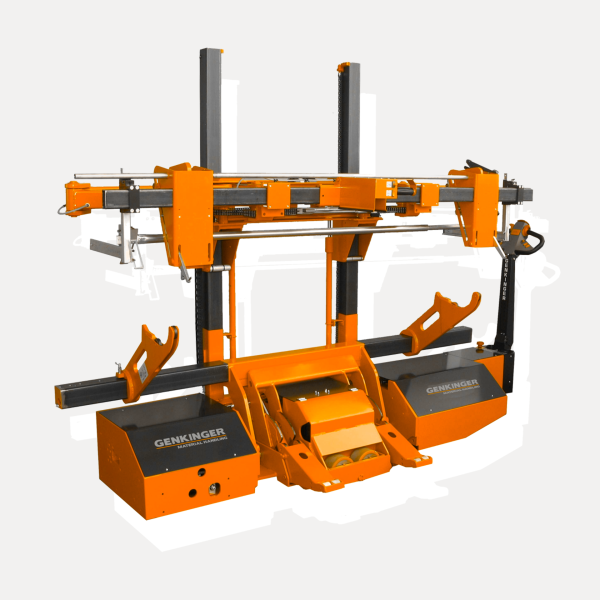

EE-KHUR 20...50 GEV: Dish storage trolley

- Load capacity Q up to 5.000 kg

- Machine width 1.200 mm - infinity

Describe your case.

We will be glad to advise you.

Describe your case.

We will be glad to advise you.

This is where Genkinger comes in:

We will also find a suitable solution for your transport challenge

Make distance at the:

Transportation

To move demanding loads as quickly and safely as possible between warehouses and machines, specific solutions are needed for internal transport. On the short and medium haul, it is important to be maneuverable and agile. On the long haul, speed counts and thus the adaptation of the industrial trucks to inclines, smooth or uneven road surfaces.

For the transport of loads for which there is no standard, Genkinger develops and manufactures special vehicles. Adapted also to your local conditions.

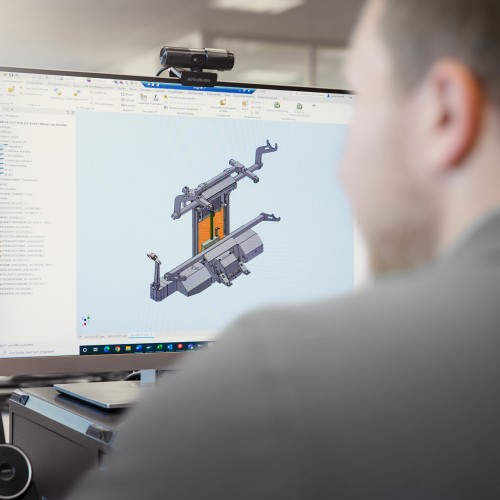

Project

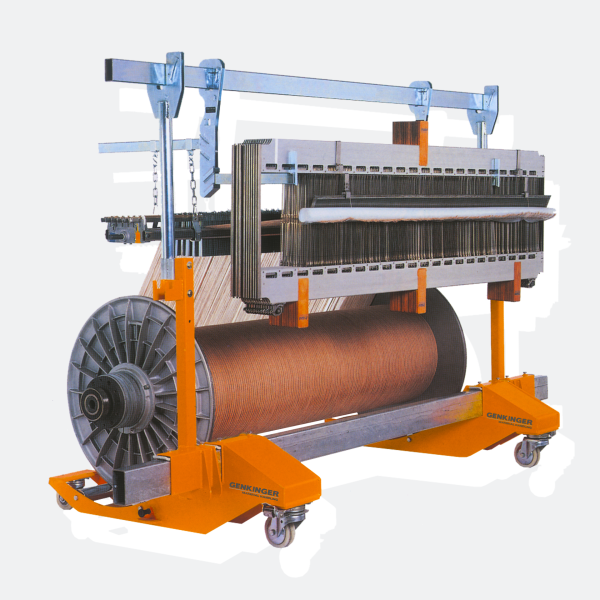

TLS 20...30: Transport trolley

- Load capacity Q 2000 kg, 3000 kg

- Machine width 600 mm - infinite

Project

EE-KHUR 20...50 GEV: Dish storage trolley

- Load capacity Q up to 5.000 kg

- Machine width 1.200 mm - infinity

Describe your case.

We will be glad to advise you.

Describe your case.

We will be glad to advise you.

This is where Genkinger comes in:

We will also find a suitable solution for your transport challenge

More movement at the:

Store

In order to access goods quickly or to use material alternately in production, they must be stored as close as possible. And that with a high level of security as well as maximum space-saving.

Genkinger develops transport solutions as well as storage systems. Or both at the same time. That is, when the transport solution can also be an intermediate storage facility. Or the warehouse itself simply moves heavy and bulky loads at the push of a button.

Project

TLS 20...30: Transport trolley

- Load capacity Q 2000 kg, 3000 kg

- Machine width 600 mm - infinite

Describe your case.

We will be glad to advise you.

Describe your case.

We will be glad to advise you.

This is where Genkinger comes in:

We will also find a suitable solution for your transport challenge

The linchpin of the:

Mounting

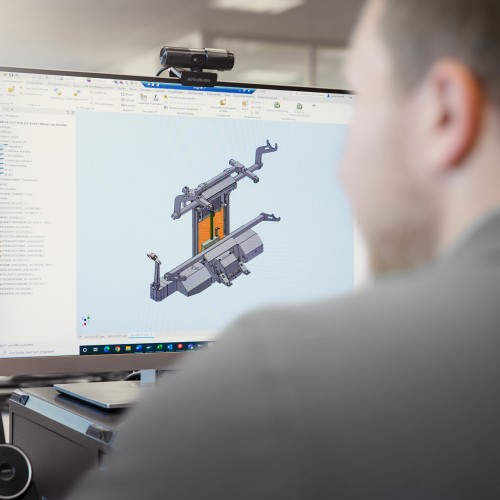

Before further assembly can begin, the load must be picked up, secured, transported and brought into the correct position. In the best case, the vehicle allows for different applications in order to respond flexibly to fluctuating demand within production.

Project

TLS 20...30: Transport trolley

- Load capacity Q 2000 kg, 3000 kg

- Machine width 600 mm - infinite

Describe your case.

We will be glad to advise you.

Describe your case.

We will be glad to advise you.

This is where Genkinger comes in:

We will also find a suitable solution for your transport challenge

Start project request

Briefly describe your material handling vehicle requirements or tell us about your daily challenges in warehousing technology or textile technology.