We achieve more:

Up to high

in narrow aisles

Picking up heavy loads high, precisely and safely, inserting them and transporting them in confined spaces is a case for high lift trucks with four-way lifting technology. Genkinger specializes in solving transport tasks even on specific machines, such as the insertion of upper warp beams in the textile industry.

An important aspect in the planning of an industrial truck for industry and commerce is also always to avoid intermediate handling of the heavy loads.

- Pick-up by tines, clamps, grabs, load arms

- Load capacity from 300 kg to 10,000 kg

- Drawbar, driver's platform, driver's seat, drawbar/pushbar

- Optionally also as AGV/FTS

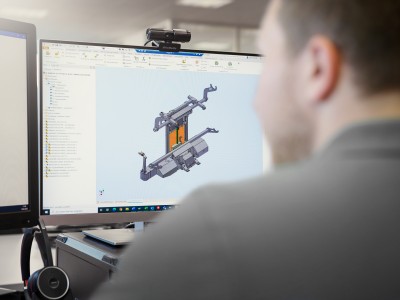

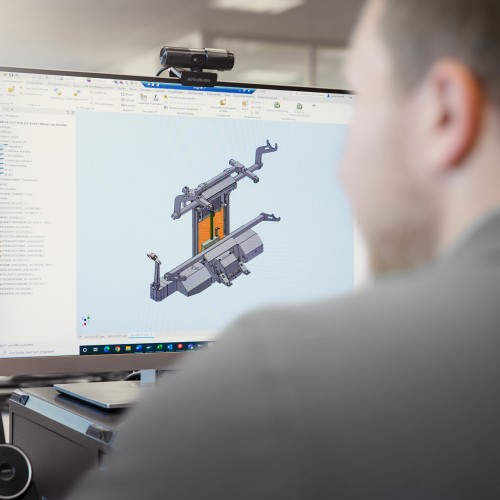

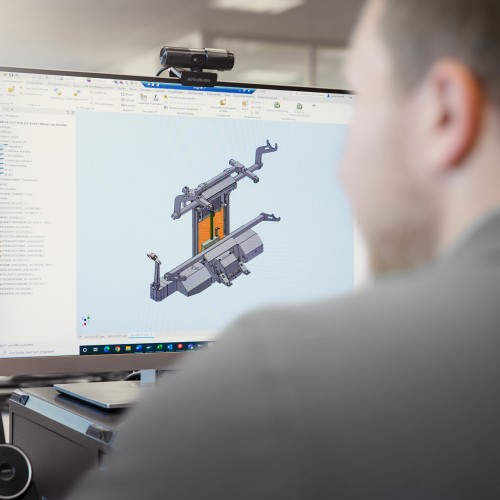

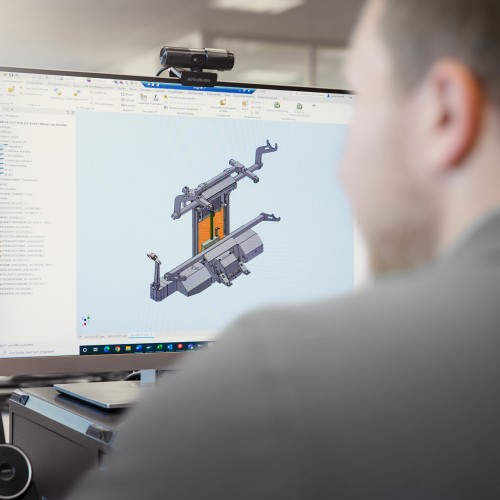

More mobile assembly:

Pivot point

for assemblies

If the further assembly of assemblies or vehicles and machines is to be kept as flexible as possible, new transport solutions are needed within manufacturing as an alternative to rails and belts. As the size, weight and bulkiness of assemblies increase, so do the demands on transport. The pivotal point is also the device for safe pickup as well as precise feeding of the assemblies.

Genkinger designs industrial trucks with a high level of vertical integration. This enables specific configuration, even for different transport tasks with a single vehicle.

- Simple and safe operation via radio remote control and safety interrogations

- Flexible (rotary) fixtures with different adapters or vacuum grippers

- Optimized for small batch assembly, vehicle manufacturing and mechanical engineering

Project

EGG 50: High lift truck

- Load capacity Q 5.000 kg

- Working height 4.600 mm

Describe your case.

We will be glad to advise you.

Describe your case.

We will be glad to advise you.

This is where Genkinger comes in:

We will also find a suitable solution for your transport challenge

For all cases:

The abbreviation

for long goods

Whether for window construction or the construction of wind turbines - in both cases, long material has to be moved. With great safety and in the smallest possible area. With special driving skills and usually under time pressure. In the best case, the long goods are picked up from the side, transported and unloaded. In any case, it needs an industrial truck that meets all the requirements for user-friendliness, chassis and load securing.

Do you need a robust standard all-rounder for your long goods? Or the configured special solution for intralogistic special transports? - Genkinger manufactures transport solutions even for loads that are very long and also heavy and bulky.

- Four-way and multi-way trolley with mast feed

- Prismatic forks, pipe grabs, manipulators, troughs

Move pallets wisely

When the standard

comes up against limits

Pallets and especially the Euro pallets make the transfer and storage of goods easy, since they have the advantage, among other things, that they can be picked up with pallet trucks or forklifts from all four sides. The challenges are also not in the standard situations when manipulating pallets.

Special pallets, heavy loads or top-heavy pallets, slopes during loading and unloading, storing pallets lengthwise are just a few examples of situations in which lift trucks and stackers can reach their limits in the standard version. It is precisely for these cases that Genkinger offers transport solutions for pallets in various configurations.

- Euro pallets, one-way pallets, special pallets

- Store and retrieve pallets, transport, hand over

Standards are the way to go

Move at the first go

more

Rectangular loads such as small load carriers (KLT) or skeleton containers are standardized systems. The fact that they can be stacked on top of each other and/or grouped together next to each other (e.g. on Euro pallets) means that a larger number of the rectangular loads can be transported at the drop of a hat as well as stored in a space-saving manner.

In principle, picking up by forklift or pallet truck is simple. Smaller units are picked up on pallets. Larger boxes, bins or containers have feet that can be driven under from all four sides.

For particularly heavy rectangular loads and uneven distributions, Genkinger will develop special solutions for you for loading, unloading, transporting, storing, as well as feeding within production.

Project

EGG 50: High lift truck

- Load capacity Q 5.000 kg

- Working height 4.600 mm

Describe your case.

We will be glad to advise you.

Describe your case.

We will be glad to advise you.

This is where Genkinger comes in:

We will also find a suitable solution for your transport challenge

We'll get to grips with that, too:

Round and heavy

Pipes, rolls, drums, coils have only one thing in common: they are round. Otherwise, the challenges of transporting round loads increase with, among other things, weight, diameter, length, material sensitivity and, if applicable, hazard class.

Genkinger develops vehicles for the demanding transport of round loads. Highly specialized in safe pick-up and precise delivery. With simultaneous flexibility for other transport tasks as well.

- Sensor controlled clamps

- Camera based recording

- Radio remote control

Things run smoothly with us:

Safe on all

ways through the

weaving and knitting

Special lifting and transport vehicles are needed for inserting, changing and storing warp beams. This is because roll-shaped heavy loads such as warp beams require particularly safe handling.

Genkinger has been the specialist for lifting and transport vehicles for warp beams for many decades. We are in close exchange with leading textile machinery manufacturers to equip small and large textile companies around the world with innovative transport and material handling systems for warp beams.

- Transport and insertion of upper and lower warp beams

- Warp beam change with harness

- For full warp beams, half warp beams, warp beams and canisters

- High lift truck, low lift truck, transport truck

Project

EE-KHHG 15: High lift truck

- Load capacity Q 1.500 kg

- Machine width 1200 mm - infinite

Project

EE-GYR 25: High lift truck

- Load capacity Q 2.500 kg

- Machine width 1.100 mm - infinite

Project

EE-KHHR 20: High lift truck

- Load capacity Q 2.000 kg

- Machine width 1.400 mm - infinity

Describe your case.

We will be glad to advise you.

Describe your case.

We will be glad to advise you.

This is where Genkinger comes in:

We will also find a suitable solution for your transport challenge

Highlights

Start project request

Briefly describe your material handling vehicle requirements or tell us about your daily challenges in warehousing technology or textile technology.