Stock in circulation:

Access at

the touch of a button

In order to make effective use of the available storage space, storage and shelving systems using the circulating method are the ideal solution. Warp beams, docks, warp beams and goods beams are heavy rolling loads that pose special challenges for material handling and occupational safety.

Paternosters or recirculating storage enable multi-lane storage in height and width. Thanks to the circulation method, the stored goods are quickly transported to the correct working height and then quickly removed by low-lift truck.

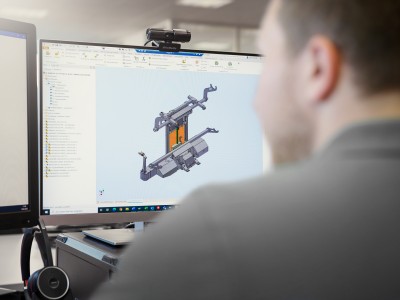

Genkinger manufactures dynamic storage systems to customer specifications. The design depends on the storage capacity as well as the number and dimensions of your goods to be stored.

- Loading and unloading from the front and rear

- Increased occupational safety

- Also over several floors with several operating points

Everything under control in the weaving & knitting mill

Sovereign security

in any situation

When transporting docks and merchandise trees, it is important to solve these three situations in particular with confidence:

- The removal of the dock from the dock winder or the removal of the fabric beam from the weaving machine

- The safe transport, also over longer distances, on small and also uneven surfaces

- The safe unwinding of the dock or fabric beam down to the floor, to intermediate heights or up to the high rack

Genkinger develops customized transport solutions for docks and goods trees with different weights, lengths and diameters, always also adapted to the conditions and requirements on site.

- Docks & fabric trees up to 3,000 kg

- Different lengths and diameters

- Also double-sided overrolling and unrolling from the floor to the high rack

Highlights

Start project request

Briefly describe your material handling vehicle requirements or tell us about your daily challenges in warehousing technology or textile technology.