Our drive:

New mobility

of tools

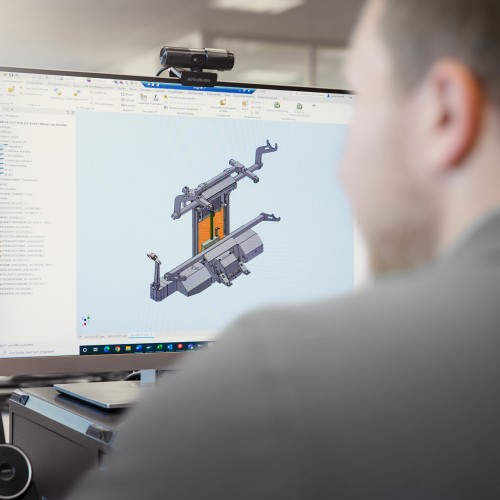

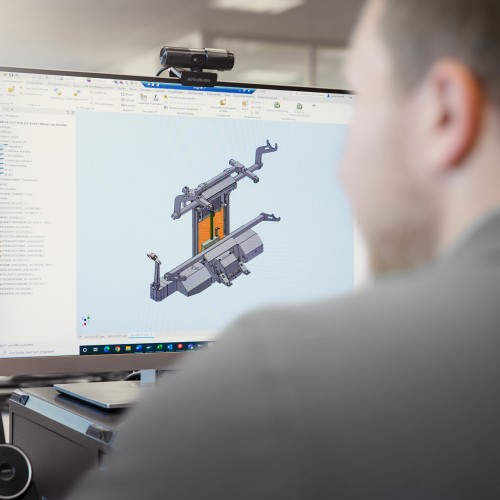

In order to lift tools safely, transport them and position them precisely in the machine, different load centers, dimensions, docking situations, entry heights and maneuvering options must be taken into account depending on the tool (punch, casting, forging, mold). In addition, there are individual requirements for operation and the degree of automation.

Based on your specification, Genkinger configures mold changers for maximum efficient use on site.

- Handling of tools from 500 kg to over 80,000 kg

- Mobile lifting tables, change carts, assembly aids

- Mobile temporary storage of tools

up to 80.000 kg

up to 8.000 mm

Everything under control at:

Tool change

The tool change is a sensitive process, as the further production process depends on it to a large extent. When inserting and removing the tool, therefore, what counts is not only speed, but above all precision.

This requires systems that are precisely adapted to the mold and the machine. For safety's sake, with a high degree of automation. Sensors, emergency switches and intelligent safety interrogations as well as all-round visibility thanks to radio remote control offer maximum protection for your tools.

Project

FAT 12: Lift tables

- Load capacity Q 1.200 kg

- Load length 1.000 mm

Project

EE-WW: Tool changing cart

- Load capacity Q 1.000 kg

- Stroke range 650 - 2.200 mm

Describe your case.

We will be glad to advise you.

Describe your case.

We will be glad to advise you.

This is where Genkinger comes in:

We will also find a suitable solution for your transport challenge

Driving like on rails at the:

Tool transport

The heavy and bulky tools are transported in front of the machine with millimeter precision and brought to the correct height. And the route to the warehouse or the tool shop must also be covered safely and intelligently.

We have decades of practical experience with tool transport. Always also specified to the paths and areas on site, optionally rail-bound or with two-way, four-way or multi-way chassis.

Project

FAT 12: Lift tables

- Load capacity Q 1.200 kg

- Load length 1.000 mm

Describe your case.

We will be glad to advise you.

Describe your case.

We will be glad to advise you.

This is where Genkinger comes in:

We will also find a suitable solution for your transport challenge